Technology

Piping Engineering and Stress Analysis Services

At the heart of our advanced engineering capabilities lies our expertise in Piping Engineering Stress Analysis, a critical domain where precision, experience, and technological acumen converge.

Our Piping Engineering Stress Analysis services cover process and piping project management, workflow optimization, and meticulous stress calculations, ensuring adherence to all legal and engineering standards.

Spearheaded by Senior Engineer Flores, our team brings over 35 years of specialized experience in process engineering, piping design, and stress analysis.

Our extensive track record encompasses work in demanding sectors such as oil & gas, chemical processing, power generation, and more, ensuring we deliver robust and reliable piping systems.

Expertise

Process and Piping Project Management: Senior Engineer Flores, a veteran in the field, manages and inspects process and piping projects. His wealth of experience in tackling clogging issues in various plants is particularly relevant to resolving C-Green’s challenges.

Workflow Optimization: Recognizing the unique requirements of C-Green, we specialize in refining workflow processes and software integrations to streamline operations tailored to the company’s size and needs.

Design and Stress Calculations: Our capabilities extend to creating comprehensive pipe design and conducting meticulous stress calculations, crucial for addressing clogging issues and ensuring adherence to all legal and engineering standards

Services

Piping Design and Analysis: Our services cover the full spectrum of piping design and stress analysis, backed by in-depth knowledge of standards like ASME B31.1, B31.3, and EN 13480.

Pipe Stress Analysis: Utilizing tools such as AutoPIPE and CAESAR II, we perform detailed stress analyses to ensure system integrity under various conditions, including static and dynamic loads.

Dynamic Analysis and Troubleshooting: Our team is adept at solving dynamic problems and troubleshooting existing plant issues, such as vibration, expansion joint failures, and support structure deficiencies.

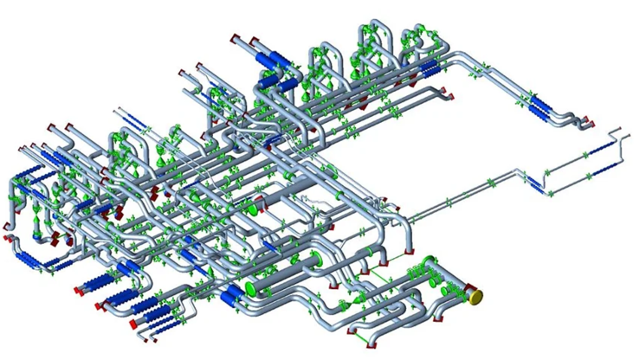

3D Modeling and Design: Employing advanced software like Openplant, Autodesk Plant 3D and CADWORX, we deliver comprehensive 3D models, facilitating clash-free and accurate plant design.

Our piping services cater to a wide range of industries and applications

Industrial Plants: From chemicals to petrochemicals, refineries, and power generation facilities.

Oil & Gas: Covering offshore projects, pipelines, and wellhead towers.

Water Treatment: Including desalination, STP, ETP, and RWTP.

Specialized Sectors: Such as bio-refineries, pharmaceuticals, and solar thermal power plants.

Our dedication to excellence ensures that every piping system designed and analyzed by our team is not only optimized for performance but also for safety, reliability, and compliance with the most rigorous industry standards. C-Green’s next plant construction will benefit from our deep-seated commitment to quality and robust engineering practices.

With SOFCO our clients gain access to a distinguished blend of experience, expertise, and cutting-edge technological practice. Let us partner with you to address your most complex piping challenges with solutions that are both innovative and practical.