Technology

Computational Fluid Dynamics (CFD)

Ansys Fluent enhances our fluid dynamics simulations with its advanced physics modeling and customizable interface.

Comprehensive Computational Fluid Dynamics (CFD)

Ansys Fluent enhances our fluid dynamics simulations with its advanced physics modeling and customizable interface, which accelerates time-to-market by harnessing the power of GPU computing, sophisticated hydrogen modeling, and workflow automation.

The software proficiently handles the complexities of hypersonic flows, capturing shock and plasma phenomena, thus streamlining development and minimizing the need for physical testing.

For wind energy solutions, Ansys enables intricate Multiphysics simulations for turbine design and efficiency optimization, suitable for a variety of environmental conditions

Fluent’s turbulence models, such as the flexible GEKO, provide simulation reliability for a wide range of scenarios.

Its multiphase flow capabilities are essential for the chemical and petrochemical industries, ensuring the scalability and performance optimization of equipment.

The combustion models within Fluent are rigorously tested for accuracy, incorporating turbulence and chemical reactions to offer comprehensive performance insights.

Furthermore, Fluent proficiently models fluid-structure interactions to facilitate the creation of robust, safe, and finely tuned designs. These simulations can be performed independently or in conjunction with Ansys Mechanical for more complex situations.

Aerodynamics

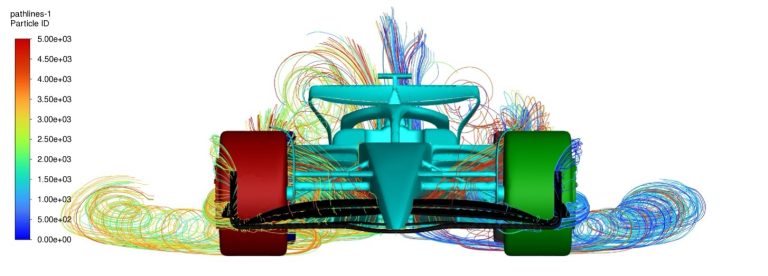

Our company’s aerodynamics simulations, which leverage both CFD and FEA, are tailored to enhance designs for drones, wind turbines, race cars, and improve cabin thermal comfort. We navigate various flow regimes—low speed to hypersonic—including turbulence and flow management.

Our precision in calculating system characteristics such as mass flow rates and pressure drops, as well as dynamic forces like lift, drag, and pitching moments, informs design and stress testing. Using Ansys Fluent, we conduct meticulous steady-state and transient aerodynamic simulations for a range of applications, from HVAC efficiency to vehicle and aircraft structural assessments.

- Drone Aerodynamics and Acoustics Simulation

- Rotor Aerodynamics Simulation

- Wind Turbine and Wind Farm Design for Green Energy

- Race Car Aerodynamic Analysis

- Cabin Aerodynamics for Thermal Comfort and Noise Mitigation

- Vehicle External Aerodynamics

- Internal Flow Analysis Covering:

- Structural Analysis for Wind Loading

- HVAC System Performance

- Drag and Pressure Evaluation for Cooling Systems

- Downforce Optimization in Vehicle Design

Multi-Phase Flows CFD Analysis

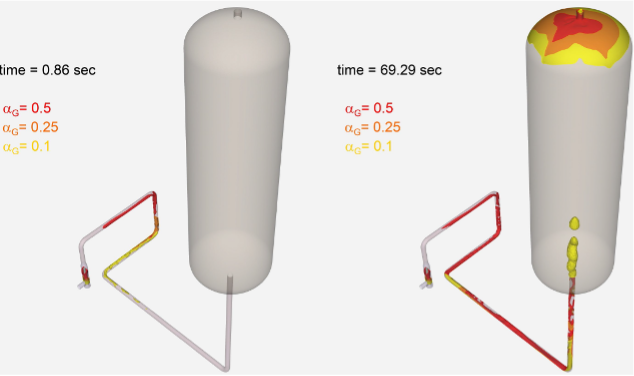

Our expertise in multi-phase flow CFD analysis enables us to simulate the complex interactions between solids, liquids, and gases. With Computational Fluid Dynamics, we capture the detailed behavior of these phase combinations in various conditions.

Our applications cover spray dynamics, particulate transport, boiling, cavitation, phase transitions, free surface flows, and mixed species interactions, which are essential in industries prone to flow-induced vibrations, such as onshore and offshore platforms, as well as subsea systems.

We tackle challenges in phase ratio changes that significantly influence dynamic forces, with implications for a range of structural frequencies. This attention to detail ensures the integrity and safety of complex engineering systems.

- Spray Design and Optimization

- Sand Erosion CFD Simulation in Oil-Gas Pipelines

- Particulate Tracking and Concentration

- Internal Combustion Engine Performance: Emissions and Fuel Economy through Reacting Flows and Fuel Injection Optimization

- Mixing Tank Simulation for Mixed Species

- Complex Offshore Structure Analysis under Oceanic Wave Interactions with Free Surface Flows

- Helicopter Water-Landing CFD and FEA Integration for Damage and Performance Prediction

- Cavitation Simulation and its Impact on Structural Integrity and Fatigue via FEA

- Gas-Liquid, Liquid-Liquid, Gas-Solid, and Liquid-Solid Flow Simulations

- Particle Flow Dynamics Analysis

Heat transfer

Our engineering team provides specialized CFD Heat Transfer Analysis services, crucial for thermal management in mechanical designs. We utilize Ansys Fluent for both steady-state and transient thermal studies, ensuring accurate evaluation of heat transfer mechanisms.

In our CFD Thermal Analysis, we go beyond traditional FEA, directly determining heat transfer coefficients from the fluid flow data, pivotal for conjugate heat transfer (CHT) assessments. We offer one-way fluid-structure interaction (FSI) analyses for situations where structural impact on flow is minimal, and two-way thermo-mechanical FSI for complex, interdependent temperature, and deformation interactions. Our approach delivers precision in thermal management for diverse mechanical systems and products.

- Cabin Aerodynamics for Optimized Thermal Comfort

- Stress Relief Heat Treatment with FEA

- Radiator and Heat Exchanger Flow Optimization

- Cross Flow Heat Exchanger Analysis for Liquid-Gas Systems

- Automotive Exhaust Gas Management

- Vehicle Thermal Management Simulations

- Electronic Systems Cooling & Heating Solutions

- Heat Exchanger Design via Simulation for Enhanced Thermal Performance

- Thermal Stress Evaluations

- Building Thermal Management with HVAC Analysis

- Turbomachinery Thermal Dynamics

Turbomachinery

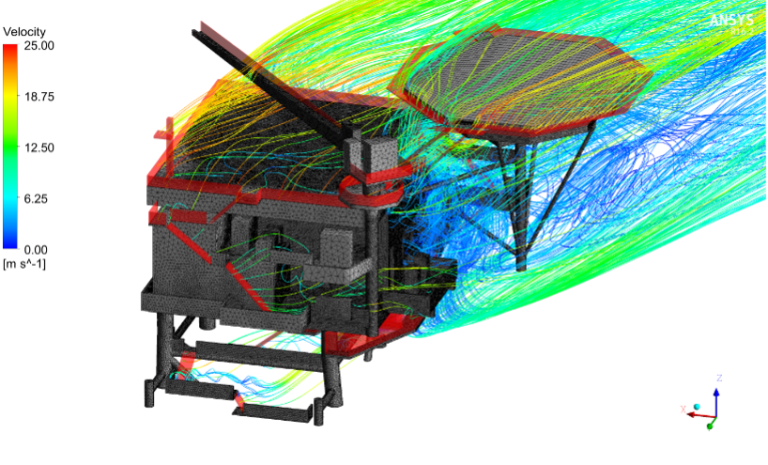

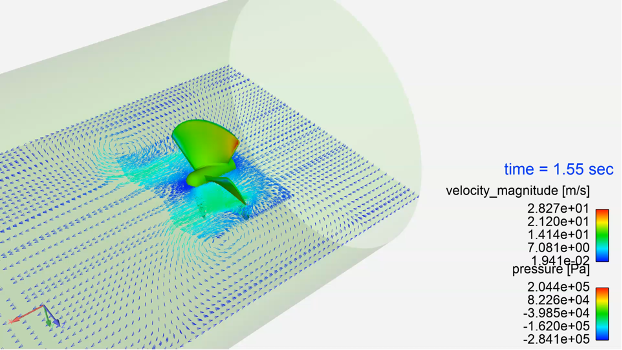

Our engineering team specializes in detailed turbomachinery analysis and enhancement, utilizing CFD and FEA simulations collaboratively. We cover all aspects of turbomachinery design, including aerodynamics, hydrodynamics, thermodynamics, vibration, and fatigue, integrating structural and fluid dynamics to address the operational complexities of fluid-structure interactions.

This integrated approach allows for the refinement of turbomachinery configurations, ensuring efficiency and longevity.

- Research and Development Support

- Evaluation and Analysis of Current Machines

- Re-design and Improvement Services

- Turbomachinery Design Enhancement

- Heat Transfer Analysis in Turbomachinery

- Turbine, Pump, and Compressor Performance Optimization

Fluid Structure Interaction (FSI)

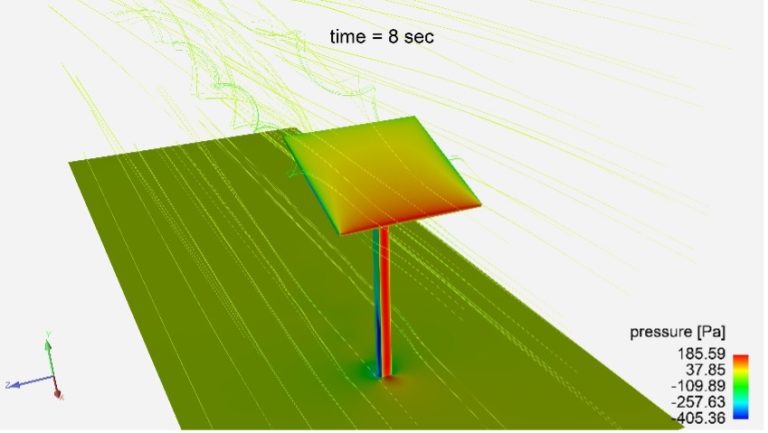

FSI calculations are essential for understanding the interplay between fluid flow and physical structures, which are inherently flexible, particularly when large or under substantial fluid loads.

Our process involves iterative computations using coupled CFD and FEA solvers, accounting for the deformation of structures due to fluid forces and the resulting changes in flow fields.

- Offshore stability including dynamic responses to wind and waves

- Simulation structural loads for floating wind turbine design, including dynamic responses to wind and waves

- Fluid Structure Interaction simulations for wind turbine design and efficiency optimization, suitable for a variety of environmental conditions.

Hydrodynamics

Our company specializes in hydrodynamic analysis of marine and offshore structures, using advanced coupled CFD and FEA simulations to evaluate FSI effects accurately.

Our expertise allows for precise predictions concerning transient resistance, propulsion efficiency, sea maneuvering, and the influences of cavitation on various marine vessels and structures.

Leveraging tools like Ansys Fluent and Ansys structural solvers, we can calculate flow-induced forces and examine the structural responses to dynamic loads, tackling issues such as vibration and fatigue. Our simulations support the design process, enhance performance, and ensure structural integrity for diverse marine applications.

- Ship stability and safety evaluation

- Turbine, pump, and compressor simulation for marine environments

- Offshore structure simulation

- Design for various offshore structures (floating, fixed, gravity-based)

- Analysis of resistance, propulsion, and sea maneuvering

Marine Propulsion

Our team applies a blend of CFD and FEA for marine propulsion systems, aiming to enhance hydrodynamic performance and optimize propeller efficiency. This method not only boosts strength and endurance but also reduces vibration, resulting in robust and efficient propulsion.

Focusing on efficiency, we refine design elements to improve propulsive power, thus optimizing fuel economy and reducing operational costs. Our team is committed to delivering optimized marine propulsion systems.

- Offshore equipment stability assessments, including buoyancy and gravity centre studies

- Drag and lift calculations on marine appendages

- Optimization for sails or wings

- Hydrodynamic design for plant & equipment

- Hydrodynamic design for tidal power systems

- Simulation for floating wind turbine design, including dynamic responses to wind and waves

- Optimization of propulsion and propeller performance

- Fatigue and lifecycle analysis of marine shafts for vibration and stress

- Erosion CFD Simulation considering hydrodynamic impacts

- Torsional Vibration Simulation using coupled CFD and FEA software for component interaction